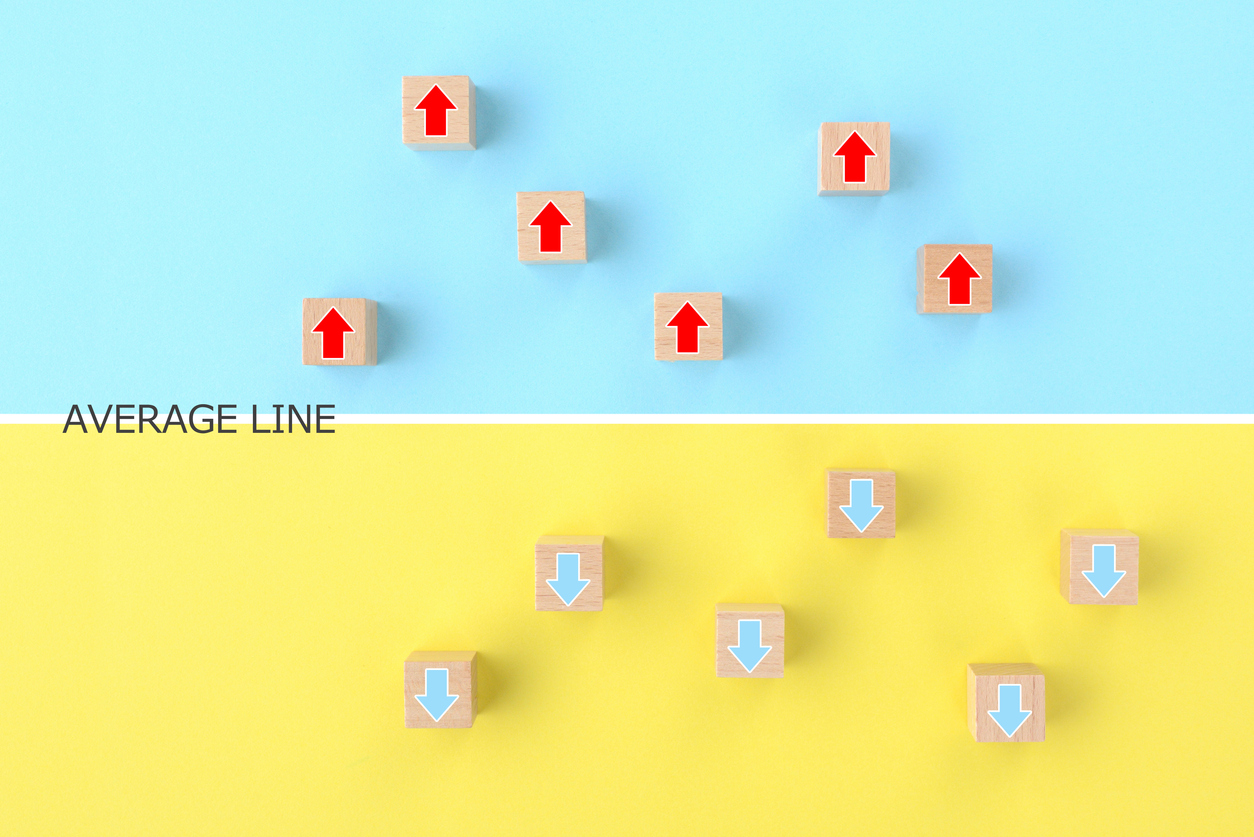

Earlier this year, we posted about FDA’s new revision for the OOS Guidance for Industry. The new revision allows ‘averaging’ results from a pool of replicate results even though one of them is OOS for ‘certain circumstances.’ This was the most significant change in this revision. So the question is, can you always average? If not, when can you average?

The guidance states ..there may be cases where the test method specifies appropriate acceptance criteria for variability and a pre-defined number of replicates from the final diluted sample solution to arrive at a result. For example, an HPLC test method may specify both acceptance criteria for variability and that a single reportable result be determined by averaging the peak response from a number of consecutive, replicate injections from the same test vial. In these cases, and given the acceptance criteria for variability are met, the result of any individual replicate in and of itself should not cause the reportable result to be OOS.

It would be inappropriate to read only the last part of the above statement “the result of any individual replicate in and of itself should not cause the reportable result to be OOS” and make quality decision without considering the whole context. It must be noted that the results discussed here are obtained from the same test vial and justification for averaging the replicates comes from the inherent assay variability of the method. How do we define assay variability and where is it documented? The assay variability can be determined based on data obtained during method validation. It is important to set acceptance criteria for assay variability for replicate results in the method itself in addition to the method validation report. It is also important to define ‘assay acceptance’ criteria for replicate results in addition to System Suitability criteria clearly in the method.

Finally, there was no change in the revised guidance document regarding borderline results that are within specification. Even though average of the replicate results is passing, if it is close to the specification limit, it should also raise a concern. One cause of the result could be that the batch was not formulated properly. Batches must be formulated with the intent to provide not less than 100 percent of the labeled or established amount of active ingredient (§ 211.101(a)). This would also be a situation where the analytical result meets specifications, but caution should be used in the release or reject decision.

If you have any questions relating to your site’s OOS investigation program and enhancing OOS investigation procedures, please contact us at LCS@LachmanConsultants.com.